ESCHSORB - Exhaust gas cleaning with activated carbon injection in a dilute phase process

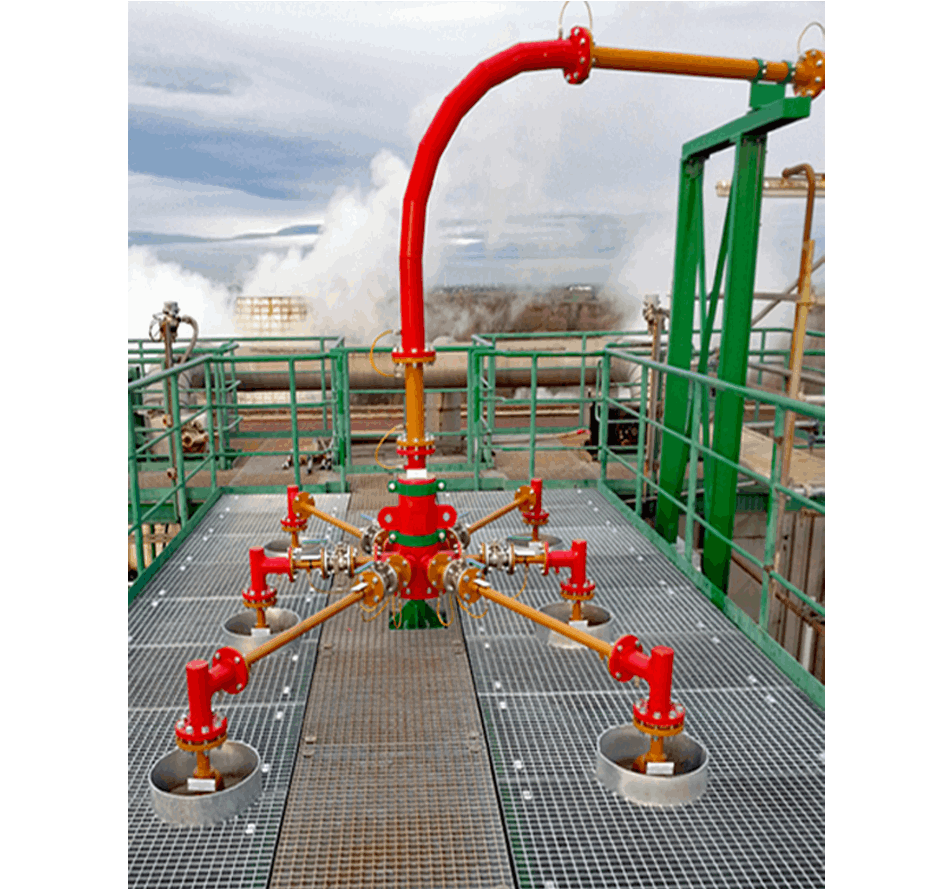

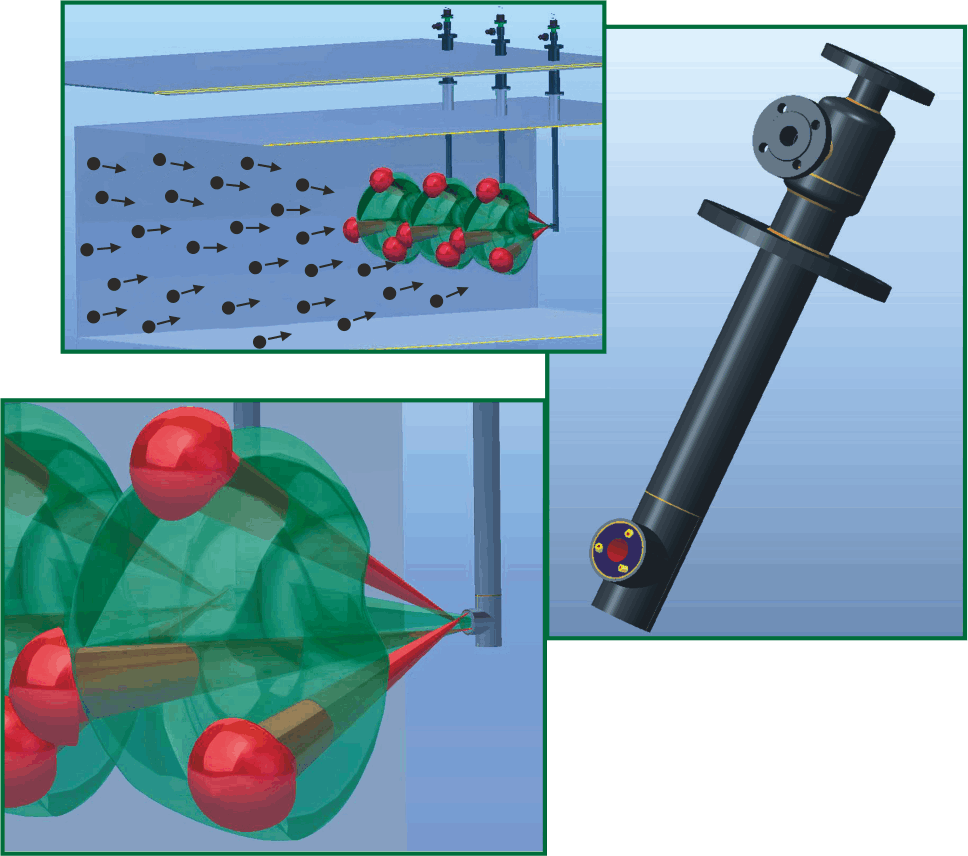

Metering and injection of activated carbon into the exhaust gas cleaning system to facilitate the adsorption of dioxins and mercury. The entrained flow reactor implements the uniformly distributed injection (one feed line for up to ten injection points) of additives such as activated coke and/or lime into the exhaust pipes of sintering belts, electric arc furnaces, rotary kilns for manufacturing cement, in waste incineration facilities and power plants for the adsorption of dioxins and mercury.

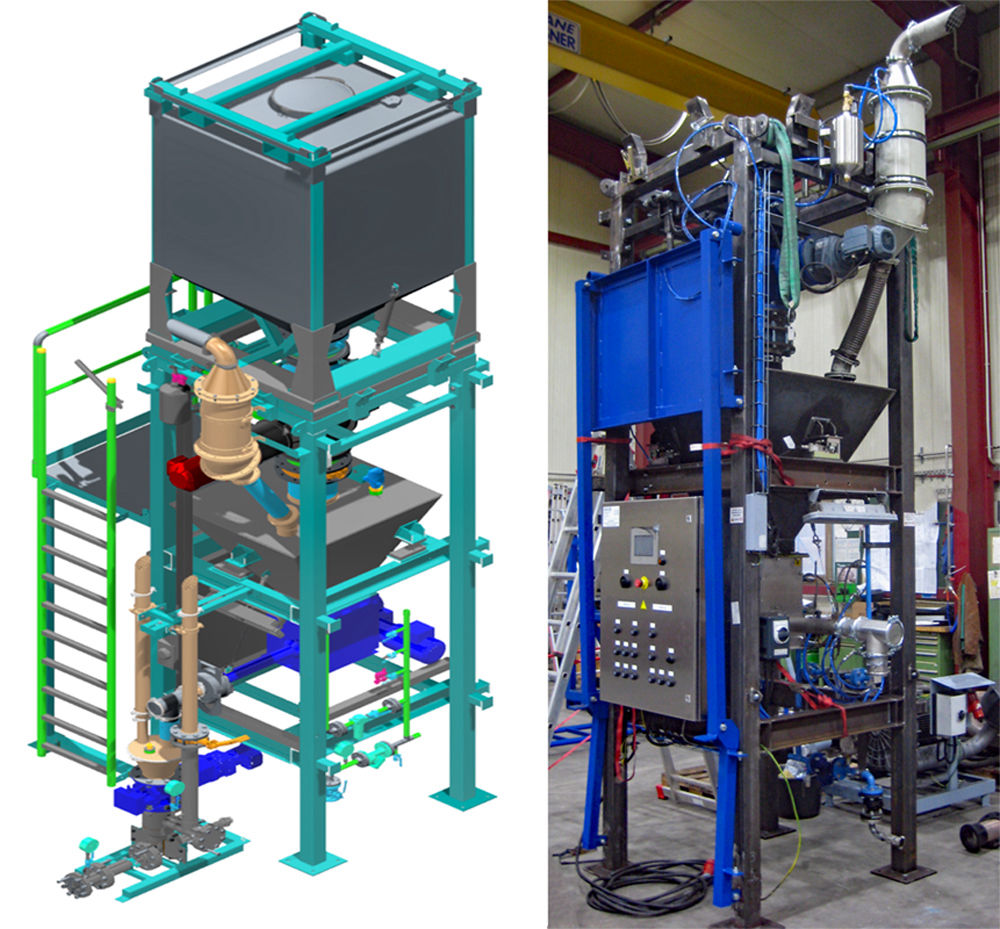

For the gravimetric metering and injector conveyance of dusts.

(With current ATEX approval for dust)

For a dilute phase conveying system that connects with the injection lances of the flue gas duct.

(Mercury reduction with activated carbon)

A high level of pollutant emissions are caused by thermal power plants and other incineration facilities that operate with fossil fuels (particularly hard coal, lignite or natural gas) or biogenic fuels.

To achieve a successful energy transition and, in particular, to meet the climate goals, we are also addressing this problem.

These pollutants, particularly mercury emissions, can be reduced significantly with appropriate technology and processes.

To do so, E.S.C.H. GmbH has developed successful technologies and performed long-term testing with the objective of coming a bit closer to compliance with the mercury limits.

Free AI Website Software