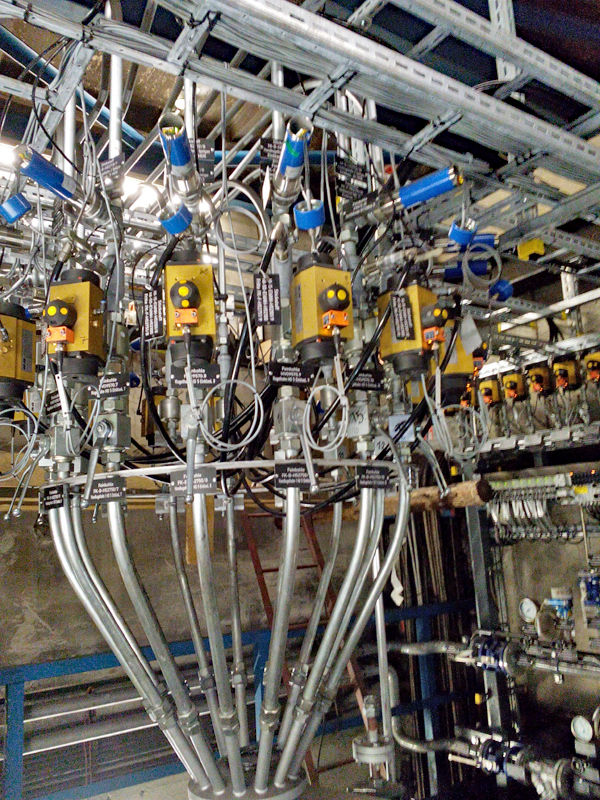

PCI+® S

Injection of pulverized coal into the tuyères of blast furnaces using a static distributor

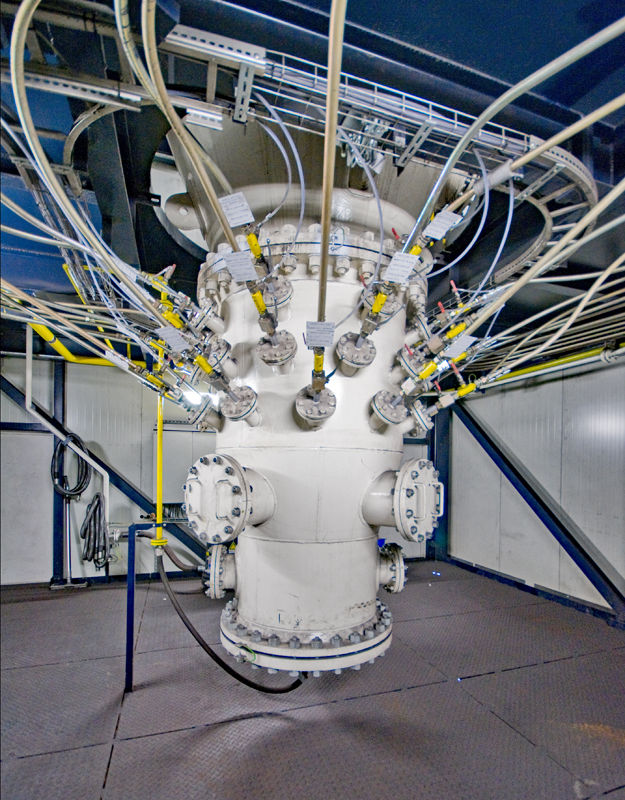

PCI+® V

Injection of pulverized coal into the tuyères of blast furnaces using a distributor vessel

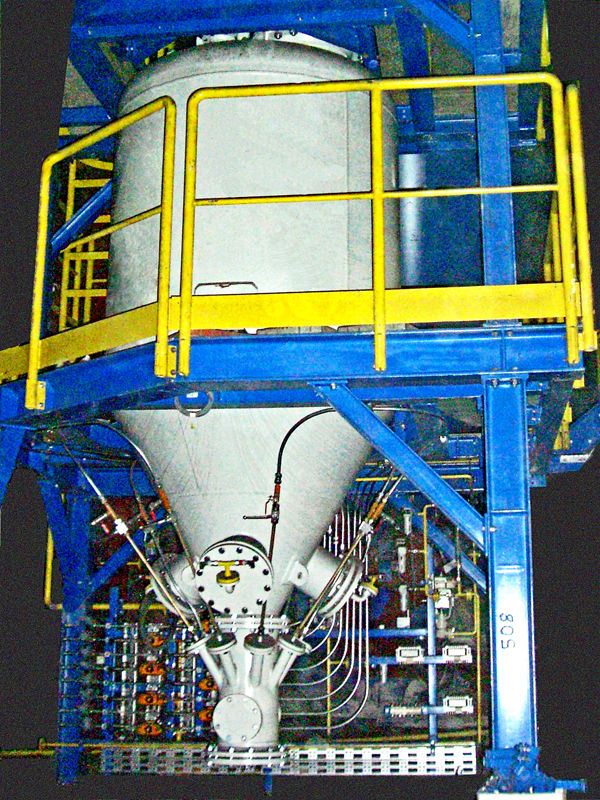

PCI+® VC

Injection of pulverized coal into the tuyères of a Cupola by means of a vessel-distributor