Fluidization and homogenisation in conveying vessel, pressure valves and bins

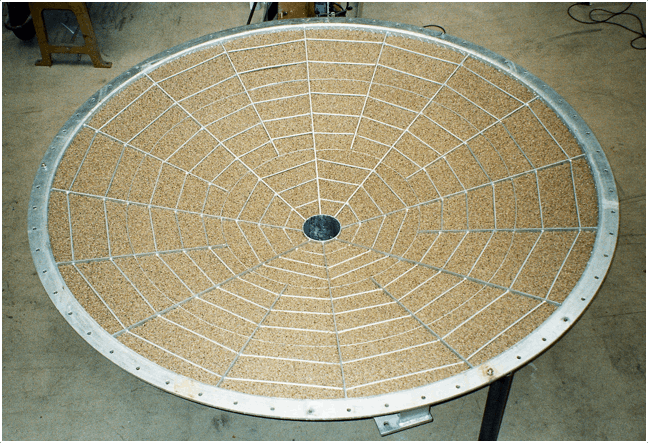

A special stamping technology is used with sand and synthetic resin to manufacture high-strength filter bottoms or filter elements with flat surfaces, up to a diameter of about 600 mm.

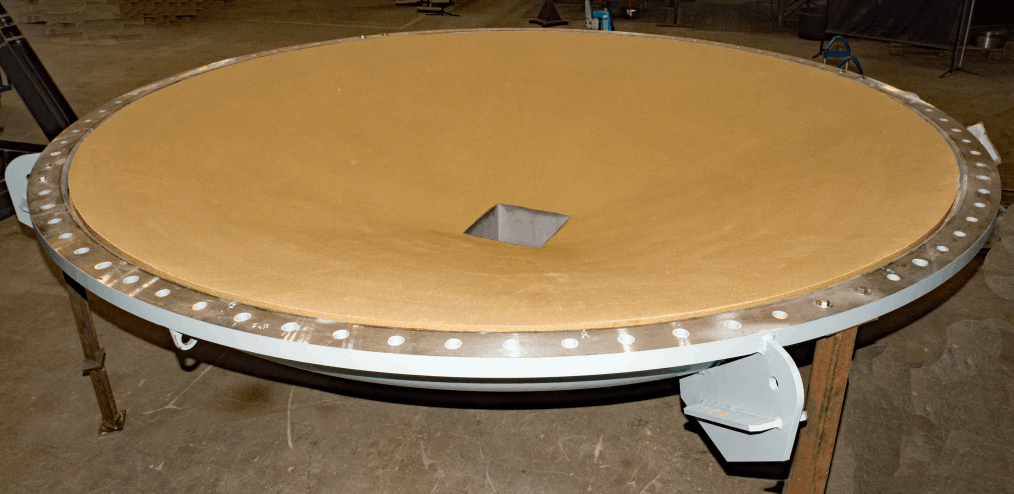

Due to a special layer technique, the tamping mass, which is air-permeable, can also be used with larger cross-sections, even with container bases that are tapered toward the bottom. The filter bottoms manufactured ac-cording to this method, with diameters up to 4000 mm, can be used as silo discharge bottoms, distributor bottoms and homogenising bottoms. Their robust design makes these bottoms highly durable and they can be walked on without difficulty. The even surfaces and the uniform distribution of the fluidisation gas across the bottom guarantee optimum material discharge. Adapted processes allow the filter bottoms to be relined just as in a retrofitting procedure in existing silos and containers.

Filter bottoms that are temperature-resistant up to 300 °C can be produced for special applications.