The aim of our current research and development projects in the fields of thermal, mechanical and biotechnological process technology is the development of applications in the industry.

In close cooperation with industrial partners we perform technological and energetic process analyses and derive the required measurements for an optimized process design.

Due to the modern installations and equimpent in our test centre we are able to preprocess different materials on a laboratory or small scale. Furthermore we perform complexe procedural investigations.

Our qualified personnel and our know-how ensure competent performances.

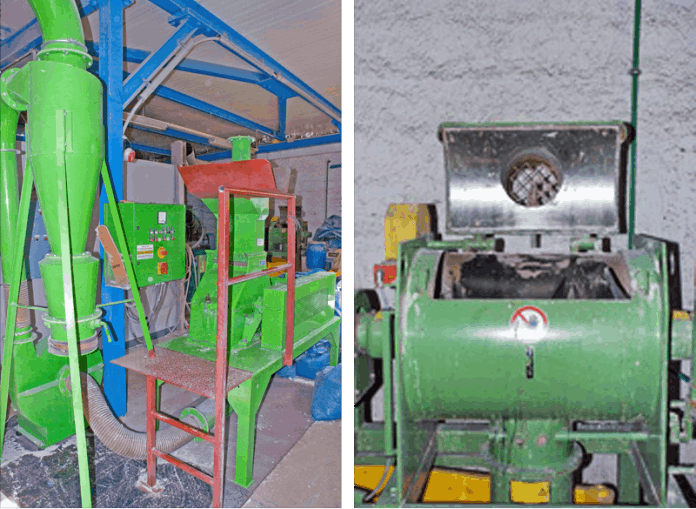

Mechanical process engineering

Processing of solid mineral and organic substances

- crushing, grinding and milling

- sieving and stream classification

- pelletization and balling

- mixing and homogenization

Processing of residual and waste materials targeting on the manufacturing of products with a particular material composition and special physical properties.

Material flow management and recipe development for raw and residual materials.

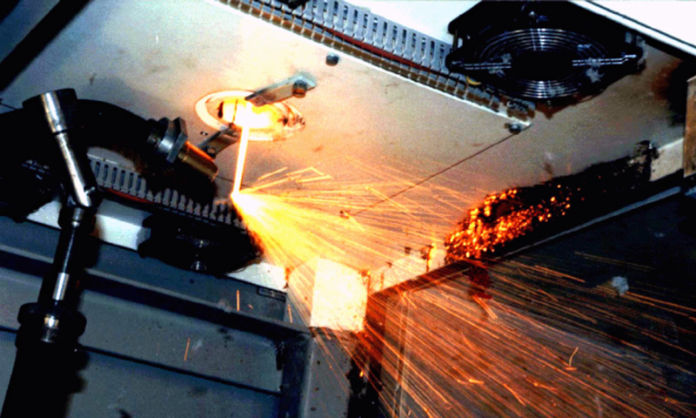

Thermal technology of production process

Transformation and finishing of materials and energy.

Energetic use of industrial and municipal waste products in order to provide more efficient methods for the transformation and use of energy and energy sources for the economy.

Material flow management and recipe development for raw and residual materials,

Thermal treatment in the rotary kiln, the sintering ladle,

Thermal treatment and melting in high-temperature chamber furnaces (also including rinsing with protective gas),

Measuring of the melt viscosity,

Fuming of mineral melts to fillers,

Microwave supporting processes.

Biological process engineering

Process development and laboratory services

Gas analyses

Cost-effectiveness calculations and consultation

Range of biogas serviceses